PHOTOS GALLERY

HVAC – EFFECTIVE AND EFFICIENT SOLUTIONS – SUPPLY, MAINTENANCE, AND REPAIRS OF HVAC EQUIPMENT:

YORK PRODUCTS

YORK air handling unit.

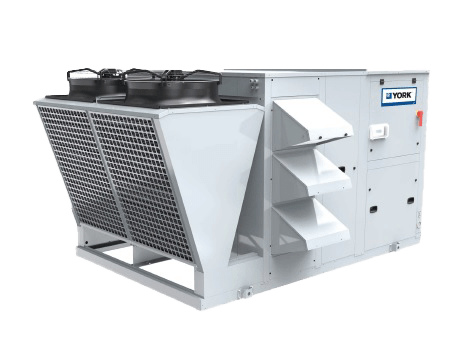

YORK PRODUCTS

YORK roof top package unit.

YORK PRODUCTS

YORK air cooled chiller.

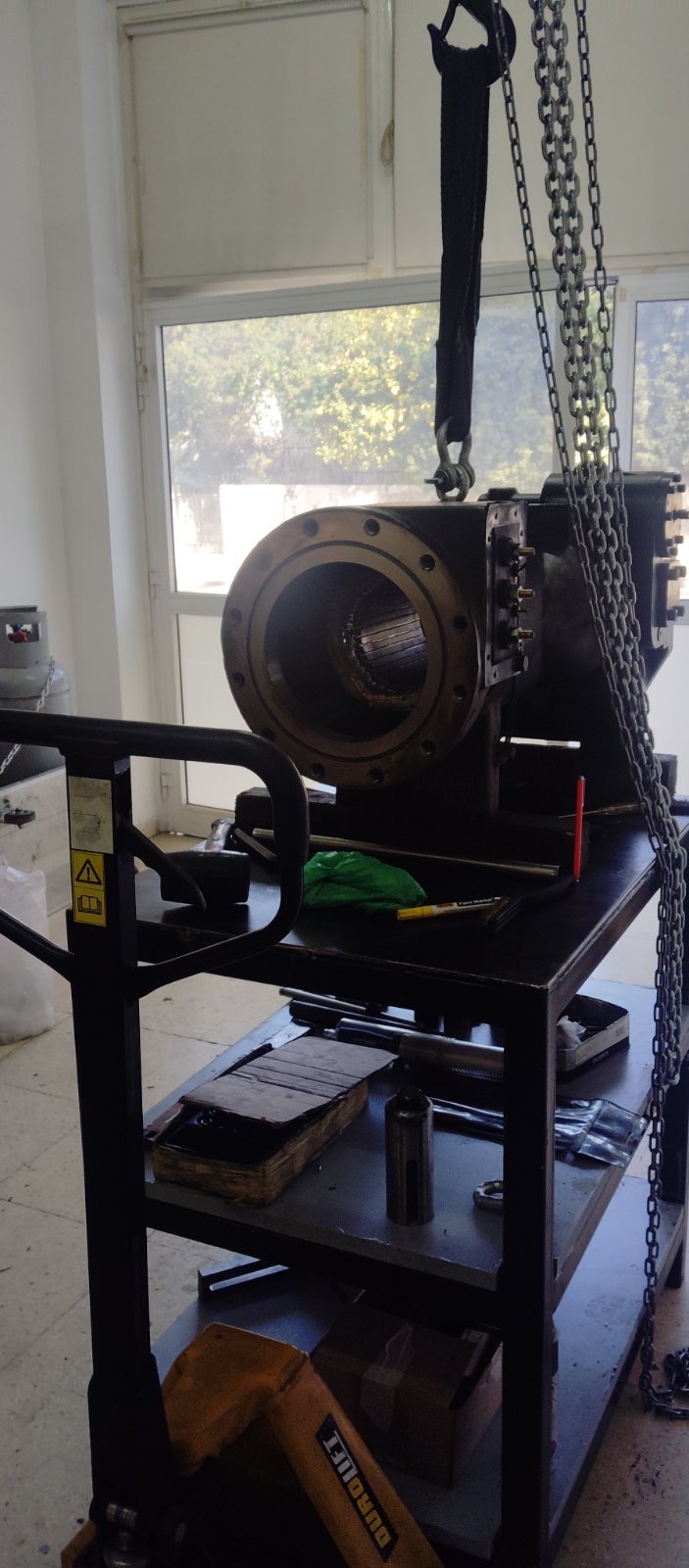

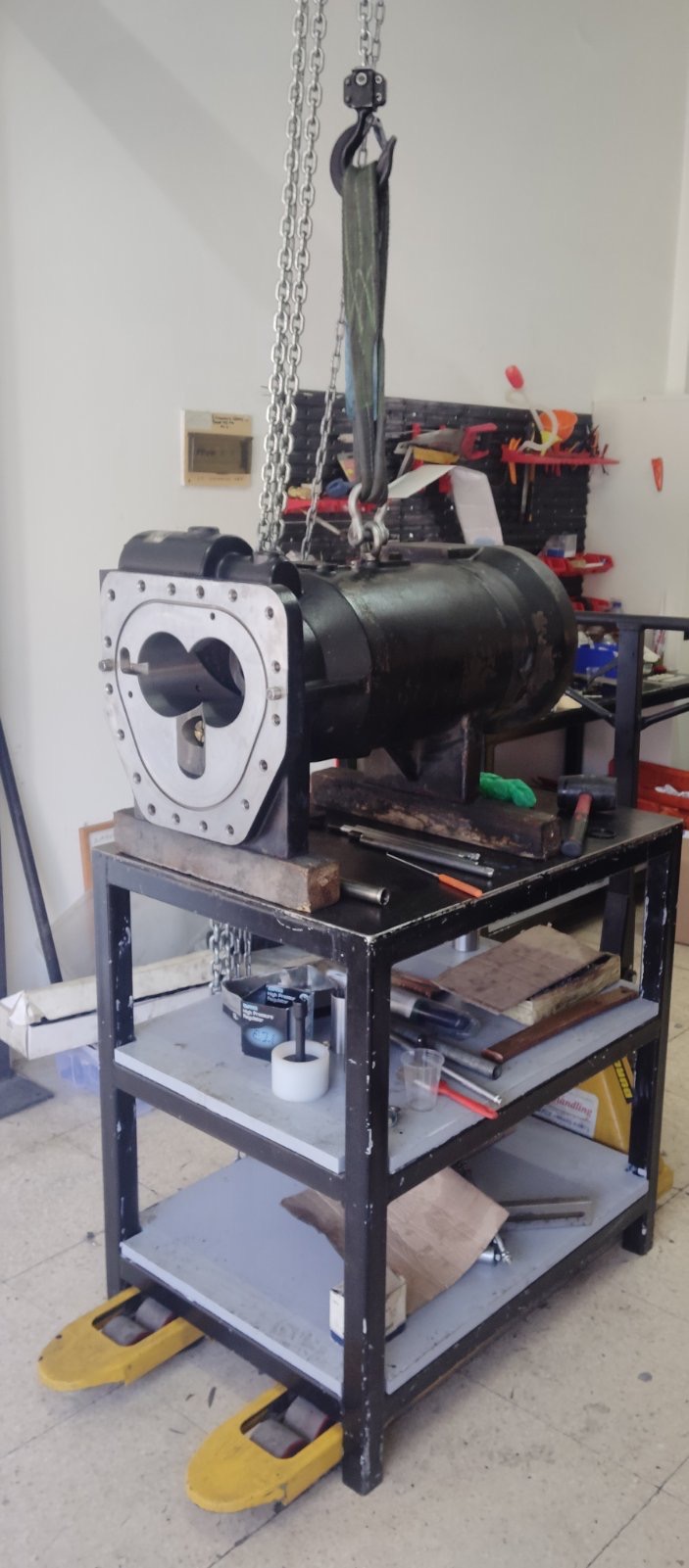

LARNACA – FEBRUARY 2025

Compressors’ overhaul and rebuild.

LARNACA – FEBRUARY 2025

Compressors’ overhaul and rebuild.

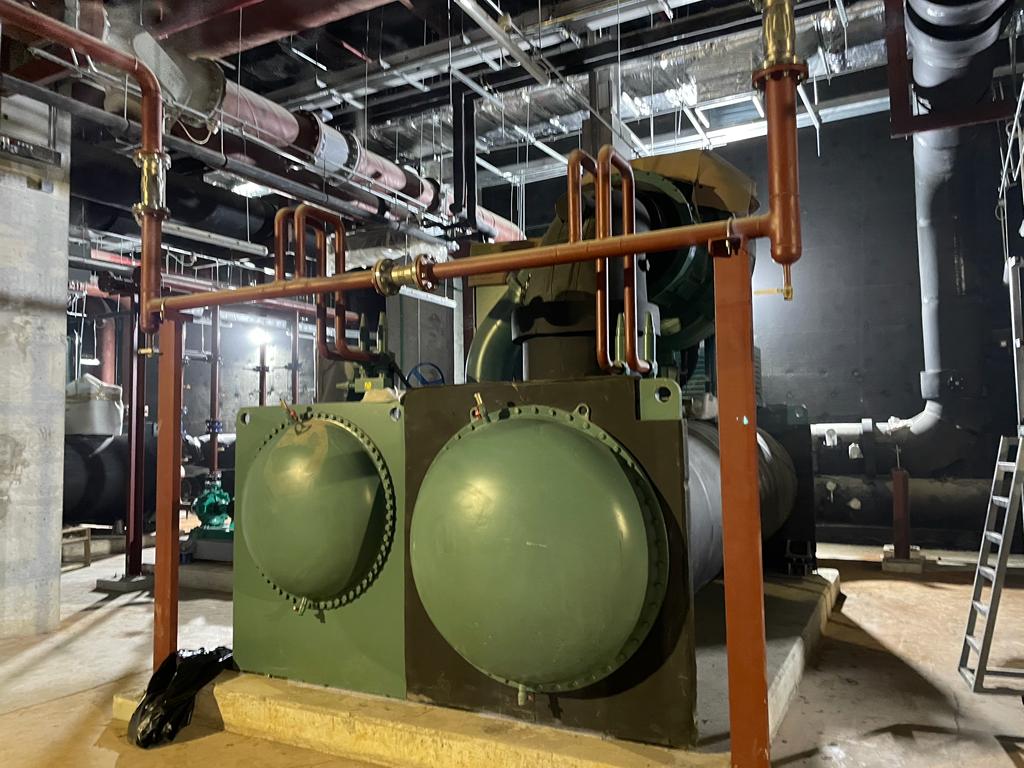

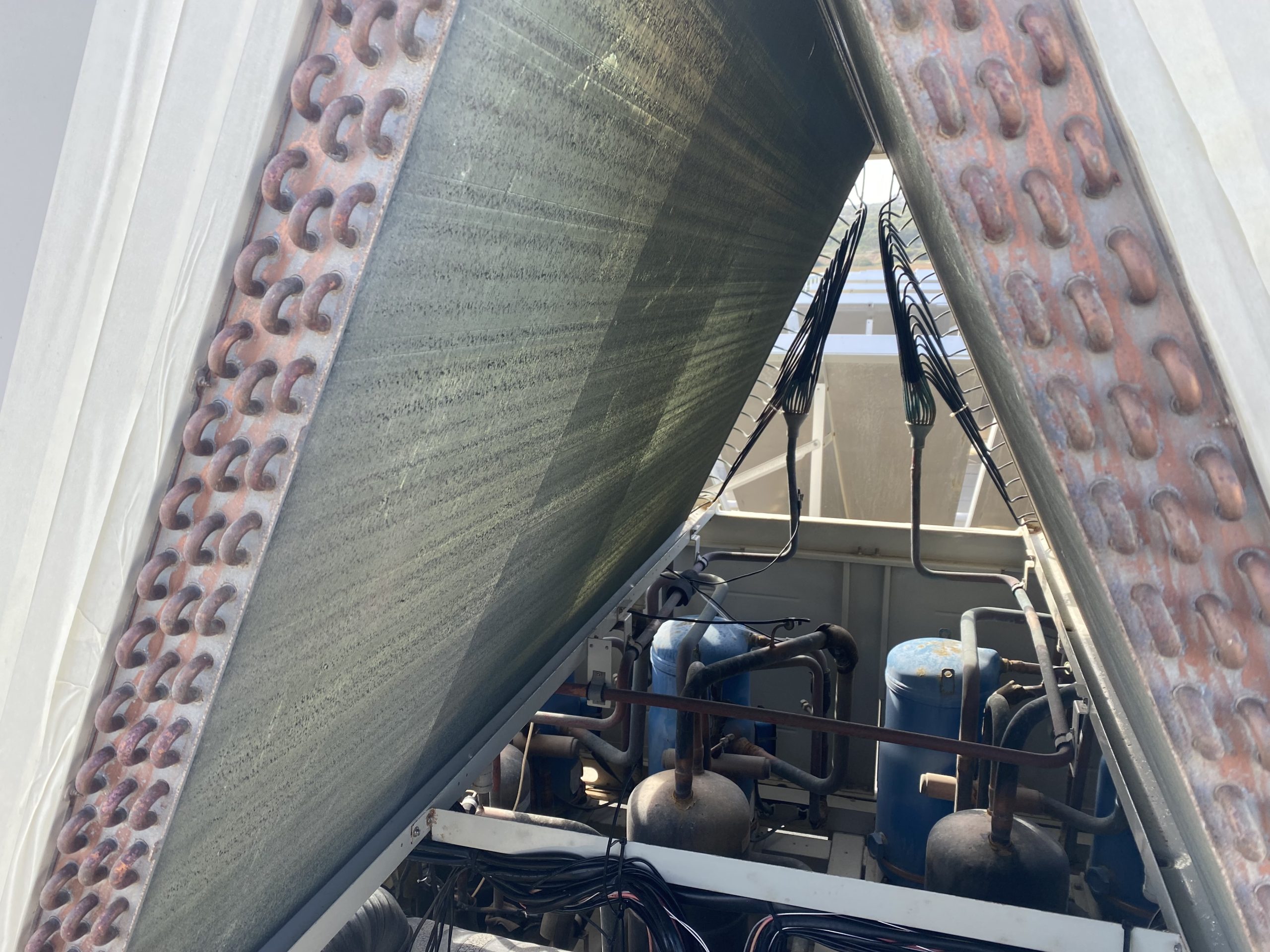

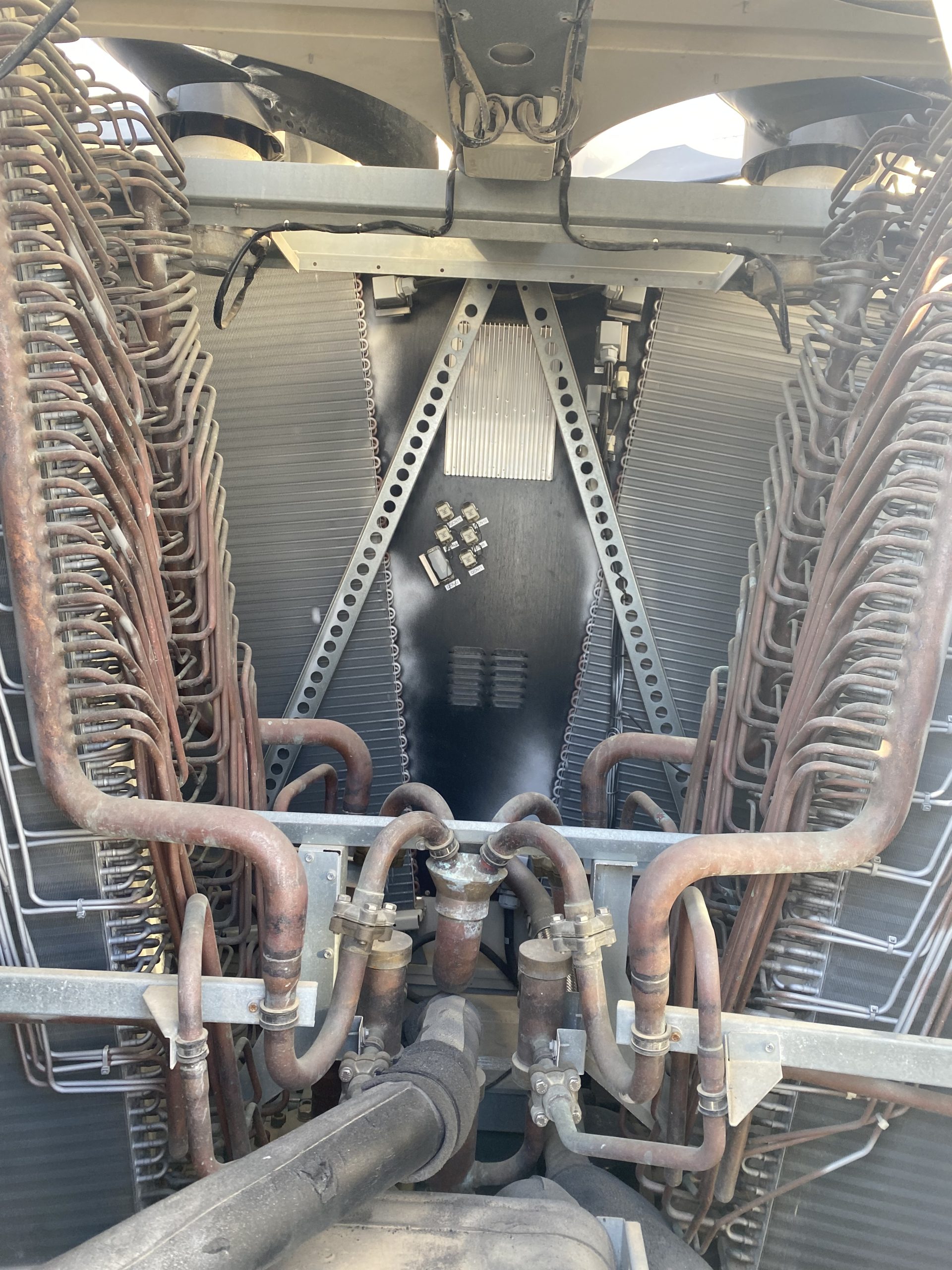

MY MALL, LIMASSOL – NOVEMBER 2023

Machinery maintenance.

The specific machinery is JOHNSONS CONTROLS – YORK and aged 15 years.

MY MALL, LIMASSOL – NOVEMBER 2023

Machinery maintenance.

The specific machinery is JOHNSONS CONTROLS – YORK and aged 15 years.

CYPRUS CASINO, LIMASSOL – JULY 2022

Start up of YORK centrifugal, water cooled chiller.

CYPRUS CASINO, LIMASSOL – JULY 2022

Supply and installation of YORK centrifugal, water cooled chiller.

MYCOREX MUSHROOMS FARM, LARNACA – MAY 2020

Supply and installation of YORK air cooled chiller.

MYCOREX MUSHROOMS FARM, LARNACA – MAY 2020

Supply and installation of YORK air cooled chiller.

LARNACA, OCTOBER 2017

Supply and installation of YORK screw, air cooled chiller.

EPOXY COATING – EFFECTIVE AND EFFICIENT SOLUTIONS IN ANTI – CORROSION PROTECTION OF HEAT EXCHANGER CONDENSERS’ FINS:

CONDENSER FINS TOTALLY DESTROYED DUE TO CORROSION

In this case, the condenser fins have totally been destroyed, due to corrosion. It’s necessary to purchase a new condenser.

In order to protect condenser fins against corrosion, the ideal scenario is to apply epoxy coating for preventive reasons, before the first signs of corrosion appear, i.e. immediately after the machinery installation. However, in case this has not been done, and corrosion has already started, then epoxy coating should be applied immediately, so as to prevent further corrosion and wear of the fins, which would lead to the creation of huge unnecessary costs such as higher consumption of electricity, replacement of condensers, total destruction of the machinery, and reduced cooling efficiency.

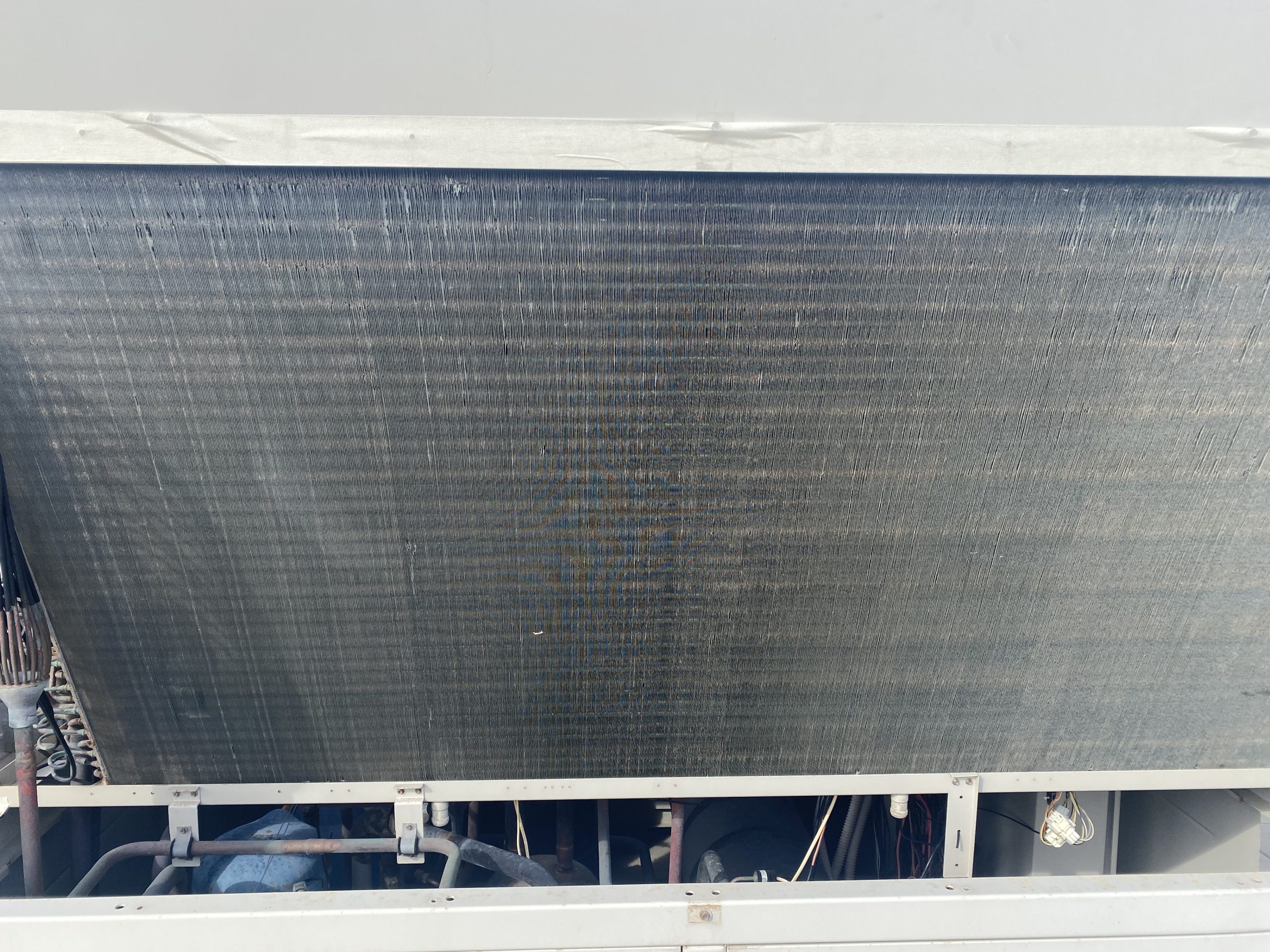

CONDENSER FINS PARTIALLY DESTROYED DUE TO CORROSION

In this case, corrosion has started but has not yet destroyed the condenser fins totally, i.e. the biggest part of the total area of the coils is unaffected.

It’s absolutely necessary to apply epoxy coating immediately, so as to prevent further corrosion and wear of the fins, which would lead to the creation of huge unnecessary costs such as higher consumption of electricity, replacement of condensers, total destruction of the machinery, and reduced cooling efficiency.

MELISSI BEACH HOTEL & SPA, PROTARAS – MARCH 2025

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Machinery is ready for operation.

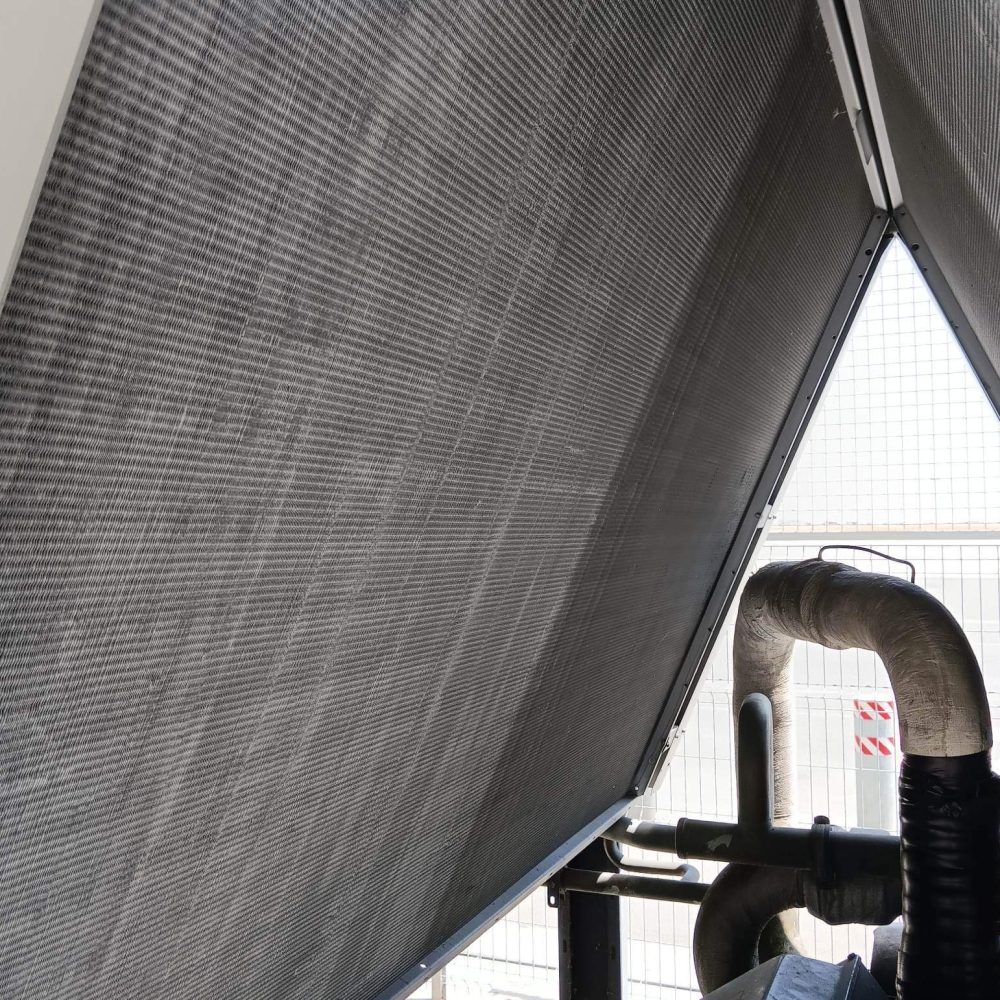

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2025

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Machinery is ready for operation.

ANTHEA HOTEL APARTMENTS, AYIA NAPA – JANUARY 2025

Image of machinery before the application of epoxy coating.

The coils are washed with the use of the appropriate chemical material – alkaline or acidid, depending on the types of impurities (e.g. oils, oxidants, etc.) existing on the condensers. Firstly, the appropriate chemical material is applied on coils and removed within minutes with the use of pressurized water. Then, the coils are thoroughly washed, with the use of pressurized water, on all sides, (externally and internally), to remove all unwanted and harmful elements (e.g. oxidation, sand, salts, etc.). The wash is continued up to the point that the dripping water is absolutely clean.

ALIATHON RESORT, PAPHOS – JANUARY 2025

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Machinery is ready for operation.

ALIATHON RESORT, PAPHOS – JANUARY 2025

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Machinery is ready for operation.

VRISSAKI BEACH HOTEL, PROTARAS – APRIL 2024

Image of machinery, before the application of epoxy coating.

Protection guards have to be removed. Machinery must be cleaned from further and impurities.

VRISSAKI BEACH HOTEL, PROTARAS – APRIL 2024

Image of machinery, before the application of epoxy coating.

Protection guards are removed. Machinery is ready for washing on all sides of the coils (externally and internally), with the use of appropriate chemical material and pressurized water.

VRISSAKI BEACH HOTEL, PROTARAS – APRIL 2024

Image of machinery, during the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

VRISSAKI BEACH HOTEL, PROTARAS – APRIL 2024

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Protection guards are placed back.

Machinery is ready for operation.

ATLANTICA APHRODITE HILLS HOTEL, PAPHOS – MARCH 2024

Image of machinery, before the application of epoxy coating.

The condenser fins are straightened with the use of special tools to ensure proper heat exchange.

ATLANTICA APHRODITE HILLS HOTEL, PAPHOS – MARCH 2024

Image of machinery for comparison purposes, before and after the application of epoxy coating.

The epoxy coating is applied at five different directions, on the coil on the right, but is not yet applied on the coil on the left.

ATLANTICA MARE VILLAGE, PAPHOS – FEBRUARY 2024

Image of machinery, before the application of epoxy coating.

Frames and protection guards have to be removed. Coils must be cleaned from furthers and impurities.

ATLANTICA MARE VILLAGE, PAPHOS – FEBRUARY 2024

Image of machinery, before the application of epoxy coating.

Frames and protection guards are removed. The external side of the coils is ready for washing with the use of appropriate chemical material and pressurized water.

ATLANTICA MARE VILLAGE, PAPHOS – FEBRUARY 2024

Image of machinery, before the application of epoxy coating.

All electrical components are removed and covered for their protection against water. The internal side of the coils is ready for washing with the use of appropriate chemical material and pressurized water.

MELISSI BEACH HOTEL & SPA, PROTARAS – FEBRUARY 2024

Image of machinery, before the application of epoxy coating.

Protection guards are removed. The frames are covered with special nylon tape for their protection against epoxy paint.

MELISSI BEACH HOTEL & SPA, PROTARAS – FEBRUARY 2024

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Protection guards are placed back.

Machinery is ready for operation.

MELISSI BEACH HOTEL & SPA, PROTARAS – FEBRUARY 2024

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Protection guards are placed back.

Machinery is ready for operation.

ATLANTICA MARE VILLAGE, AYIA NAPA – JANUARY 2024

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Machinery is ready for operation.

SANDY BEACH HOTEL, LARNACA – JANUARY 2024

Image of machinery, before the application of epoxy coating.

The coil needs to be washed with the use of appropriate chemical material and pressurized water.

SANDY BEACH HOTEL, LARNACA – JANUARY 2024

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on the right side of the coil, but not at all directions yet on the left side of the coil.

KAPETANIOS BAY HOTEL, PROTARAS – JANUARY 2024

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

KAPETANIOS BAY HOTEL, PROTARAS – JANUARY 2024

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

PAVLO NAPA BEACH HOTEL, AYIA NAPA – DECEMBER 2023

Image of machinery, before the application of epoxy coating.

The frames are covered with special nylon tape, for their protection against epoxy paint.

PAVLO NAPA BEACH HOTEL, AYIA NAPA – DECEMBER 2023

Image of machinery for comparison purposes, before and after the application of epoxy coating.

The epoxy coating is applied on the first machinery, but not yet on the next two.

PAVLO NAPA BEACH HOTEL, AYIA NAPA – DECEMBER 2023

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

Protection guards are placed back.

Machinery is ready for operation.

SUNRISE PEARL HOTEL & SPA, PROTARAS – DECEMBER 2023

Image of machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

SUNRISE BEACH HOTEL, PROTARAS – DECEMBER 2023

Image of machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

SUNRISE BEACH HOTEL, PROTARAS – DECEMBER 2023

Image of machinery, after the application of epoxy coating.

The epoxy coating is also applied on the internal side of the coils, at five different directions.

FANOS EPIFANIOU, NICOSIA – JUNE 2023

Image of brand new machinery, before the application of epoxy coating.

The frames are removed. The external side of the coils is ready for washing with the use of appropriate chemical material and pressurized water.

FANOS EPIFANIOU, NICOSIA – JUNE 2023

Image of brand new machinery, before the application of epoxy coating

The frames and fans are removed , and all electrical components are removed and covered, for their protection against water. The internal side of the coils is ready for washing with the use of appropriate chemical material and pressurized water.

FANOS EPIFANIOU, NICOSIA – JUNE 2023

Image of brand new machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

FANOS EPIFANIOU, NICOSIA – JUNE 2023

Image of brand new machinery, after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

PAPHOS – MAY 2023

Image of machinery for comparison purposes, before and after the application of epoxy coating.

The epoxy coating is applied at five different directions, on the coil on the left, but is not yet applied on the coil on the right.

PAPHOS – MAY 2023

Image of machinery for comparison purposes, before and after the application of epoxy coating.

The epoxy coating is applied at five different directions, on the coil on the left, but is not yet applied on the coil on the right.

LARNACA – MARCH 2023

Image of machinery before the application of epoxy coating.

Coils must be cleaned from furthers and impurities.

LARNACA – MARCH 2023

Image of machinery during the application of epoxy coating.

The frames are covered with special nylon tape, for their protection against epoxy paint.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

LARNACA – MARCH 2023

Image of machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

The specific machinery is twenty years old, but due to the reason that epoxy coating is applied every five years, it is almost completely unaffected by corrosion issues.

LARNACA – MARCH 2023

Image of machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

The specific machinery is twenty years old, but due to the reason that epoxy coating is applied every five years, it is almost completely unaffected by corrosion issues.

LARNACA – MARCH 2023

Image of machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

LARNACA – MARCH 2023

Image of machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Image of machinery before the application of epoxy coating.

The feathers and other impurities are removed with the use of vacuum cleaner and small, fine tools, in a proper way so that no damage is caused on the fins.

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Image of machinery before the application of epoxy coating.

The frames and fans are removed, and all electrical components are removed and covered for their protection against water. Coils are ready to be washed with the use of chemicals and pressurized water both internally and externally.

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Image of machinery before the application of epoxy coating.

The coils are washed with the use of the appropriate chemical material – alkaline or acidid, depending on the types of impurities (e.g. oils, oxidants, etc.) existing on the condensers. Firstly, the appropriate chemical material is applied on coils and removed within minutes with the use of pressurized water. Then, the coils are thoroughly washed, with the use of pressurized water, on all sides, (externally and internally), to remove all unwanted and harmful elements (e.g. oxidation, sand, salts, etc.). The wash is continued up to the point that the dripping water is absolutely clean.

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Image of machinery before the application of epoxy coating.

The coils are washed with the use of the appropriate chemical material – alkaline or acidid, depending on the types of impurities (e.g. oils, oxidants, etc.) existing on the condensers. Firstly, the appropriate chemical material is applied on coils and removed within minutes with the use of pressurized water. Then, the coils are thoroughly washed, with the use of pressurized water, on all sides, (externally and internally), to remove all unwanted and harmful elements (e.g. oxidation, sand, salts, etc.). The wash is continued up to the point that the dripping water is absolutely clean.

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Video of machinery before the application of epoxy coating

The coils are very dirty and there is a large quantity of undesirable and harmful elements (e.g. sand, salts, rusty particles, etc.). The wash is very thorough and is continued up to the point that the dripping water is absolutely clean.

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Video of machinery before the application of epoxy coating

The coils are very dirty and there is a large quantity of undesirable and harmful elements (e.g. sand, salts, rusty particles, etc.). The wash is very thorough and is continued up to the point that the dripping water is absolutely clean.

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Image of machinery before the application of epoxy coating.

Natural cleaning of the condenser is done, the fins are brushed with the use of special tool, and all electrical components are removed and covered for their protection against water. The washing procedure is completed, with the use of chemicals and pressurized water. The remaining thing to do is cover the frames with special nylon tape for their protection against epoxy paint, so as to proceed with epoxy coating application.

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Video of machinery during the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

ATLANTICA MARE VILLAGE, AYIA NAPA – FEBRUARY 2023

Image of machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

The frames are placed back.

The machinery is ready for operation.

MY MALL, LIMASSOL – JANUARY 2023

Image of machinery before the application of epoxy coating.

The condenser is washed with the use of pressurized water and the appropriate chemical material – alkaline or acidid, depending on the types of impurities (e.g. oils, oxidants, etc.) existing on the condensers. Firstly, the appropriate chemical material is applied on coils and removed within minutes with the use of pressurized water. Then, the coils are thoroughly washed, with the use of pressurized water, on all sides, (externally and internally), to remove all unwanted and harmful elements (e.g. oxidation, sand, salts, etc.). The wash is continued up to the point that the dripping water is absolutely clean.

MY MALL, LIMASSOL – JANUARY 2023

Image of machinery before the application of epoxy coating.

MY MALL, LIMASSOL – JANUARY 2023

Image of machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

FANOS EPIFANIOU, NICOSIA – OCTOBER 2022

Image of brand new machinery, before the application of epoxy coating.

FANOS EPIFANIOU, NICOSIA – OCTOBER 2022

Image of brand new machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

YGEIA CLINIC, LIMASSOL – MARCH 2020

Image of brand new machinery before the application of epoxy coating.

YGEIA CLINIC, LIMASSOL – MARCH 2020

Image of brand new machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).

LARNACA – JANUARY 2018

Image of machinery for comparison purposes, before and after the application of epoxy coating.

The epoxy coating is applied at five different directions, on the panel on the left, but not yet on the next two panels.

LARNACA – JANUARY 2018

Image of machinery after the application of epoxy coating.

The epoxy coating is applied at five different directions, on all sides of the coils (externally and internally).